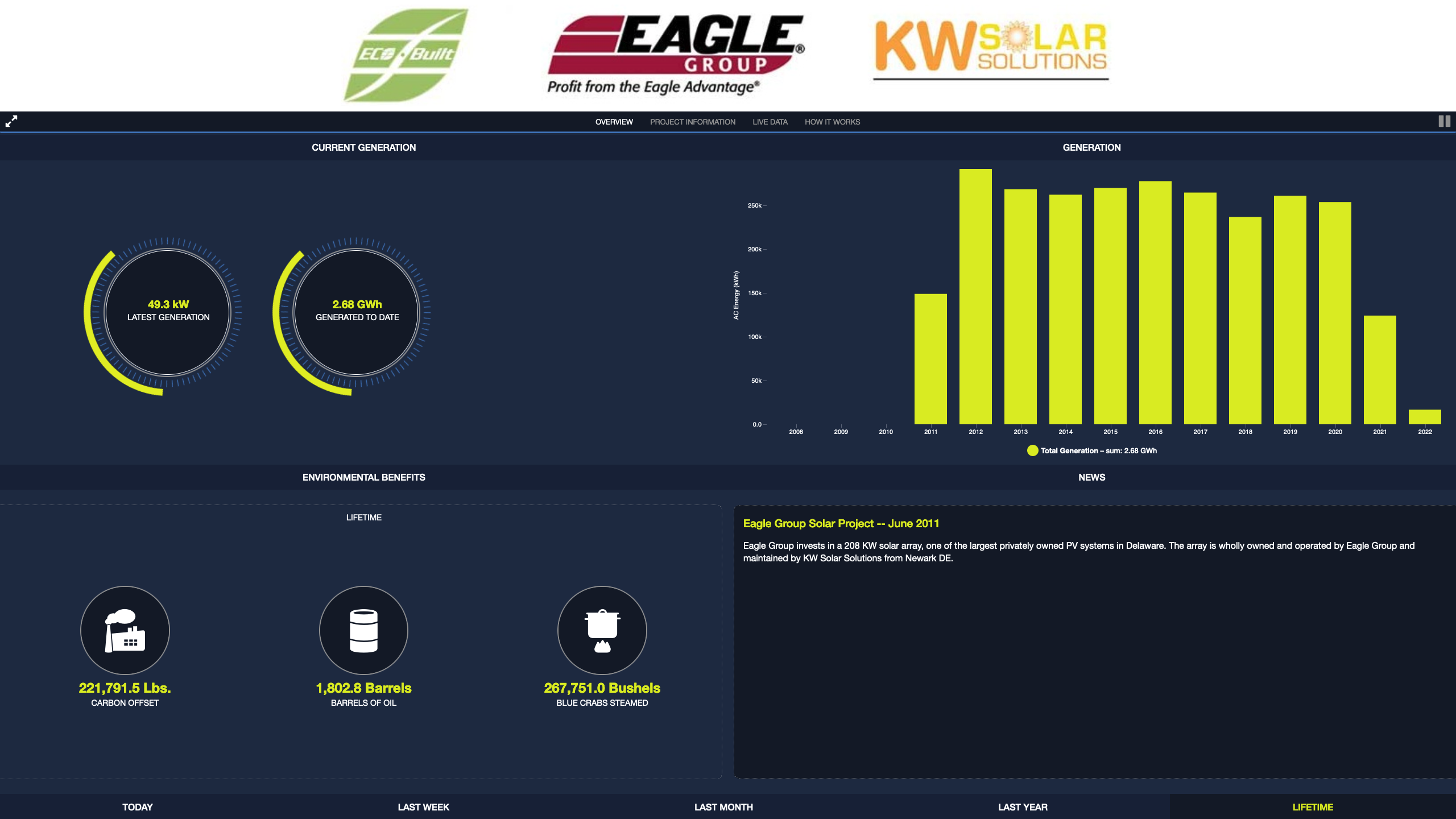

Eagle's Solar Monitoring

Eco-Built™ is how we at Eagle describe our efforts to manufacture our products in an environmentally conscious way, the same way our customers are focusing their attention on their environmental impact. It’s an ongoing commitment to incremental improvements in our manufacturing processes and facilities to conserve materials and energy while reducing emissions. Eco-Built™ is also a process. It’s how we at Eagle set goals for significant reductions in energy consumption, materials usage, and emissions, then create plans to meet those goals. Along the way, we continually monitor progress and continue to push the ball forward.

Eco-Built doesn’t hinder product development or force compromises. To the contrary, ECO-Built helps us make our products better.

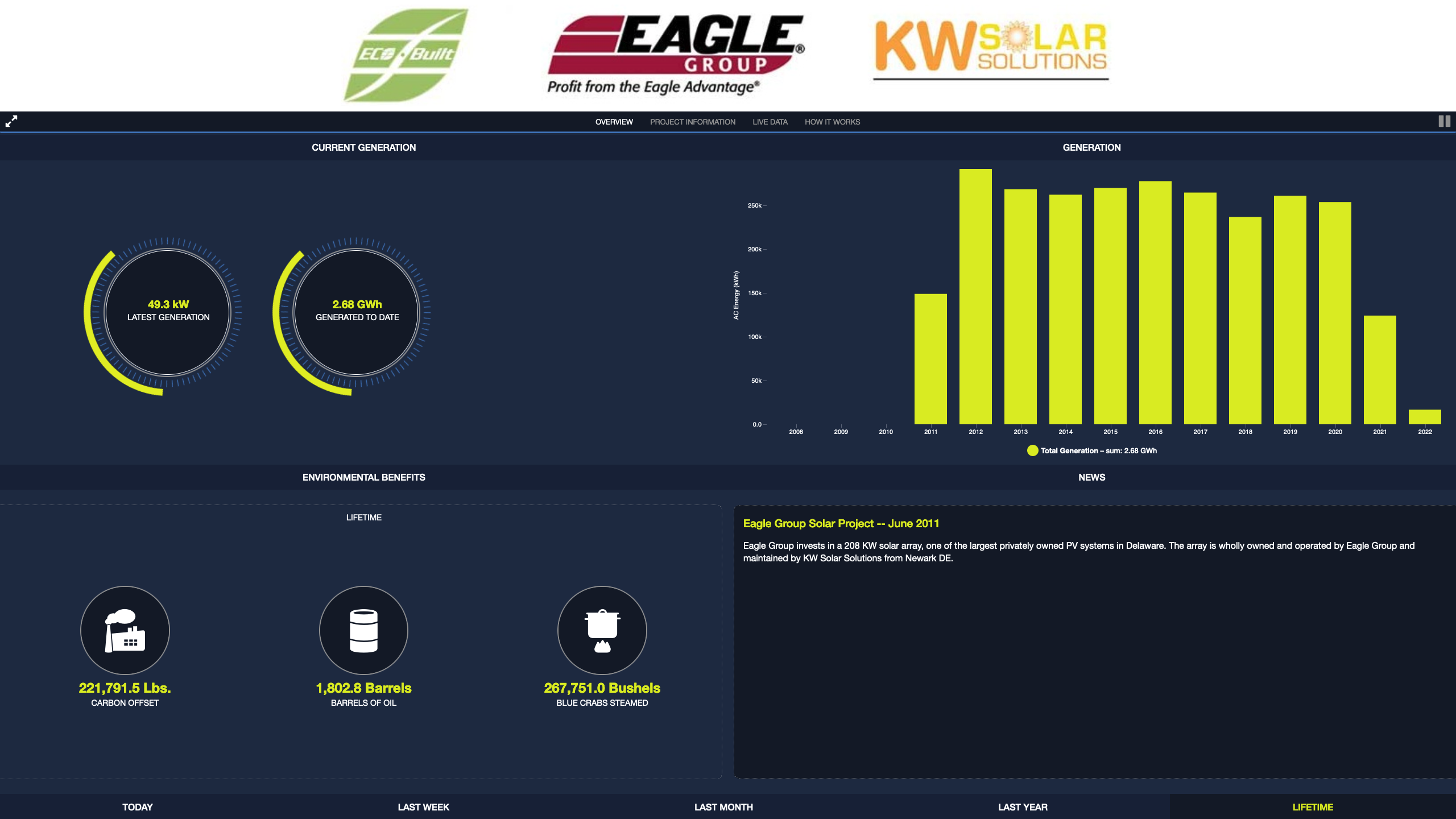

Eco-Built in action means the elimination of the annealing process to draw deep sink bowls, a single action that resulted in annual reductions of 1,230 megawatt hours of electricity, 12.7 million cubic feet of hydrogen (consumed and emitted), 42.4 million cubic feet of nitrogen (consumed and emitted), and 10 million gallons of water consumed.

It means investing a half million dollars on a new energy-reflective white roof on the Eagle plant. It means finding an alternative to vapor degreasing, thus eliminating the vapor emissions and disposal of 500 gallons of trichloroethylene annually.

Eco-Built in action even means reducing water consumption with waterless urinals.

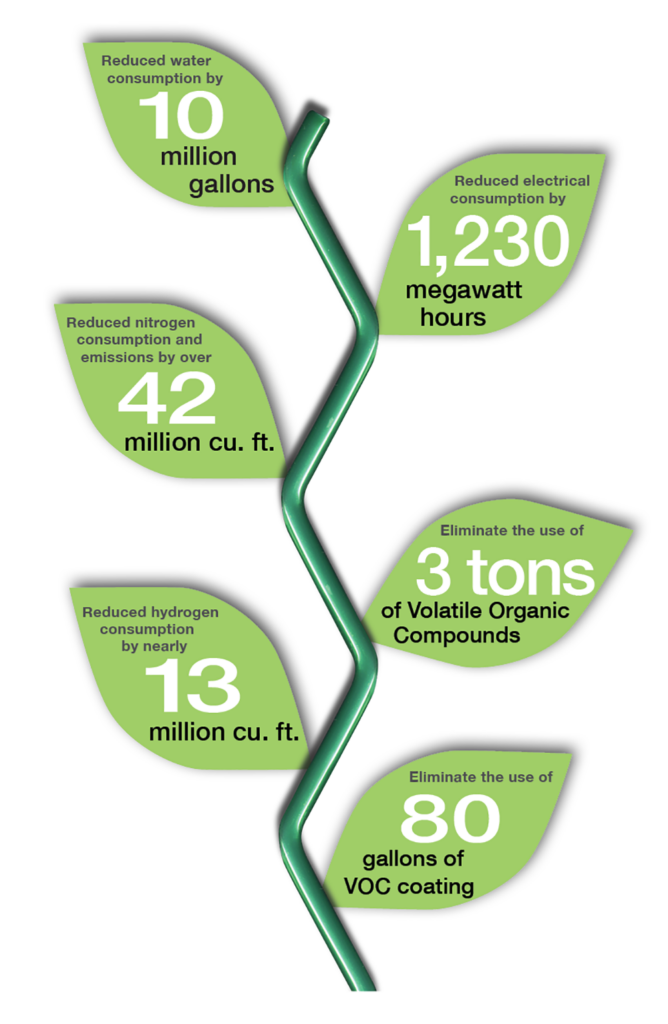

Eagle’s ECO-Built program involves employees at every level figuring out new ways to consume less, emit less, and conserve more. “It’s not enough just to produce better products. We have to produce products better. It’s a job that never ends.”

For us, waste is not an option. Whatever we use is recycled. Whatever we don’t use is recycled again. Eagle’s computer-guided sheet metal cutting machine uses a laser to precision slice recycled stainless steel for our products. This enables us to use 85% of the steel. The rest is recycled again.

Eagle’s new washing system replaces an old technology aqueous washing system and a solvent degreasing system, reducing water for process washing by 80% and eliminating the consumption and emission of 3 tons of volatile organic compounds per year.

As part of our longstanding Ecobuilt program we have committed to installing infrastructure in our parking lot to support up to 20 EV fast charging ports. Initially we will be installing two charging stations with 2 ports each which will provide capacity to charge at least 8 employee vehicles per shift. Charging will be free to Eagle Group employees. It is our hope that this benefit will make the decision to switch to EV a little easier for our employees, and in doing so support this movement to a cleaner environment and planet.

We have installed a 207 kilowatt rooftop solar electric system. To put this in a green perspective, the electricity generated by this system will eliminate the need to produce that same amount of electricity from fossil fuel sources, which will eliminate the emission of 336 tons of carbon dioxide annually.